H.W. Hill Renewable Natural Gas Project

What is Renewable Natural Gas?

What is Renewable Natural Gas?

Pipeline natural gas that is used in homes and businesses to cook and heat, used to power natural gas powered vehicles and generate electricity is composed primarily of methane, known molecularly as CH4.

Landfill gas is generated in the landfill by anaerobic (without oxygen) decomposition or organic (plant and animal) material. The by-product of this decomposition is CH4 and CO2. This methane is then collected and turned into a fuel through our process. It is considered renewable as the carbon already exists in the environment. By capturing that energy, we can provide a fuel that has one of the lowest carbon intensities available.

To collect the gas that is produced in the landfill, a vacuum is applied through a network of nearly 300 wells.

The resulting landfill gas from the Republic Services Roosevelt Regional Landfill is 53% methane, 36% CO2, 7% N2, 3.5% H2O and 0.5% O2 (with trace amounts of H2S).

The H.W. Hill Renewable Natural Gas Facility removes water, H2S, CO2, O2 and N2 (in that order) and produces pipeline gas that is over 98% pure CH4, exceeding pipeline gas quality standards. That sounds simple; it is anything but. The system includes over 4,000 horsepower of compressors, heaters, dryers, coolers and heat exchangers to process the gas. As the process is continuous each part must operate reliably and our system operators have accumulated the experience and specialized skills to operate the plant at greater than 90% reliability.

The H.W. Hill Renewable Natural Gas Facility also utilizes a unique technology for use on landfill: Cryogenic Nitrogen Removal. After all contaminants are removed with only nitrogen and methane left, the gas is used as its own refrigerant and is cooled to -280° F, liquefying the CH4, while the nitrogen remains a gas. The process then separates the nitrogen gas from the liquid methane. The methane is returned to a gas free from nitrogen and is ready to be injected into the Williams Northwest Pipeline. This process results in reduced electrical load and saves up to 16 million kilowatt hours of electricity per year relative to many other RNG production facilities.

History of RNG Project RNG Brochure

In early 2014, Klickitat PUD was focused on declining wholesale electrical power prices and the impact low prices might have on the PUD’s generation projects. Klickitat PUD’s commissioners saw this decline and directed staff to maximize the value of the assets owned by the PUD.

Staff began researching alternative uses for the gas that is produced by the landfill. At the same time Klickitat PUD was doing this research, the U.S. Environmental Protection Agency qualified landfill gas as meeting the requirements of being a cellulosic biofuel under the 2007 Renewable Fuel Standard (RFS II).

Cellulosic biofuel is the most valuable of all the biofuels identified in the RFS program because they result in at least a 60% reduction in life cycle greenhouse gas emissions.

Klickitat PUD approached Republic Services about the possibility of using the gas to fuel trucks on the landfill. It was quickly realized that the landfill could produce enough fuel in 13 days to fuel the trucks at the landfill site for an entire year!

Staff at Klickitat PUD then worked with nearly 100 companies (including developers, off-takers, equipment suppliers, engineers and even municipal agencies) to put together a project that is one of the largest and most efficient renewable natural gas facilities to be found anywhere.

Klickitat PUD is selling about 2/3 of the RNG to British Petroleum for 5 years. This contract is for a fixed amount at a fixed price and it allows us to repay the debt on the project and cover the ongoing operating and maintenance expenses. The remainder of the RNG will be sold to Puget Sound Energy starting July 1, 2020. In 2023, when the British Petroleum obligations end, Puget Sound Energy will take all of the gas produced by the facility until 2041. All of the RNG is being sold at a fixed price, which will allow the PUD to better forecast revenues and provide stable rates to our customers.

Klickitat PUD is selling about 2/3 of the RNG to British Petroleum for 5 years. This contract is for a fixed amount at a fixed price and it allows us to repay the debt on the project and cover the ongoing operating and maintenance expenses. The remainder of the RNG will be sold to Puget Sound Energy starting July 1, 2020. In 2023, when the British Petroleum obligations end, Puget Sound Energy will take all of the gas produced by the facility until 2041. All of the RNG is being sold at a fixed price, which will allow the PUD to better forecast revenues and provide stable rates to our customers. Contract Press Release

Partnerships

The Klickitat PUD H.W. Hill Renewable Natural Gas Facility is the result of a unique partnership with Klickitat PUD, Republic Services Roosevelt Regional Landfill and Klickitat County.

As part of the permitting process, Klickitat County retained the gas rights for the methane gas produced by the landfill. Klickitat County then deeded those rights to Klickitat PUD to generate renewable energy.

Additionally, Klickitat PUD has landfill gas optimization agreements with Republic Services whereby Republic Services and Klickitat PUD work collaboratively to maximize the amount of gas harvested.

|

|

Project Site Progression

The H.W. Hill Renewable Natural Gas Facility has been through a successful project succession. Each project has been an opportunity to learn, grow and build upon the previous successes.

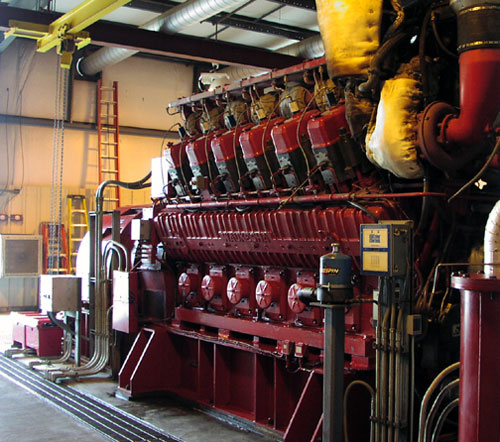

In 1999, Klickitat PUD commissioned the Landfill Gas I, or reciprocating engine project, generating up to 10.5 megawatts of electricity.

In 2010, Klickitat PUD commissioned the Landfill Gas II, or gas turbine combined-cycle project, generating up to 2 megawatts of electricity.

In 2018, Klickitat PUD commissioned the Renewable Natural Gas Project, producing up to 5,700 dekatherms per day or the equivalent of more than 18 million gallons of gasoline per year to be used as renewable transportation fuel!

With each phase of expansion, the capacity to process more fuel, more efficiently and with fewer emissions was achieved.